We are talking about a special version of the EMG eMASS® electromagnetic strip stabilisation system. There are situations where you simply can't get any further with a standard solution. In far fewer than 10 % of the roughly 80 EMG eMASS® installations worldwide, the design departmentteam of the EMG Metals Business Unit therefore has had to reach into its box of ideas and tricks. A particularly remarkable example of such a special design was recently put into operation at EMG customer thyssenkrupp Steel Europe (tkSE).

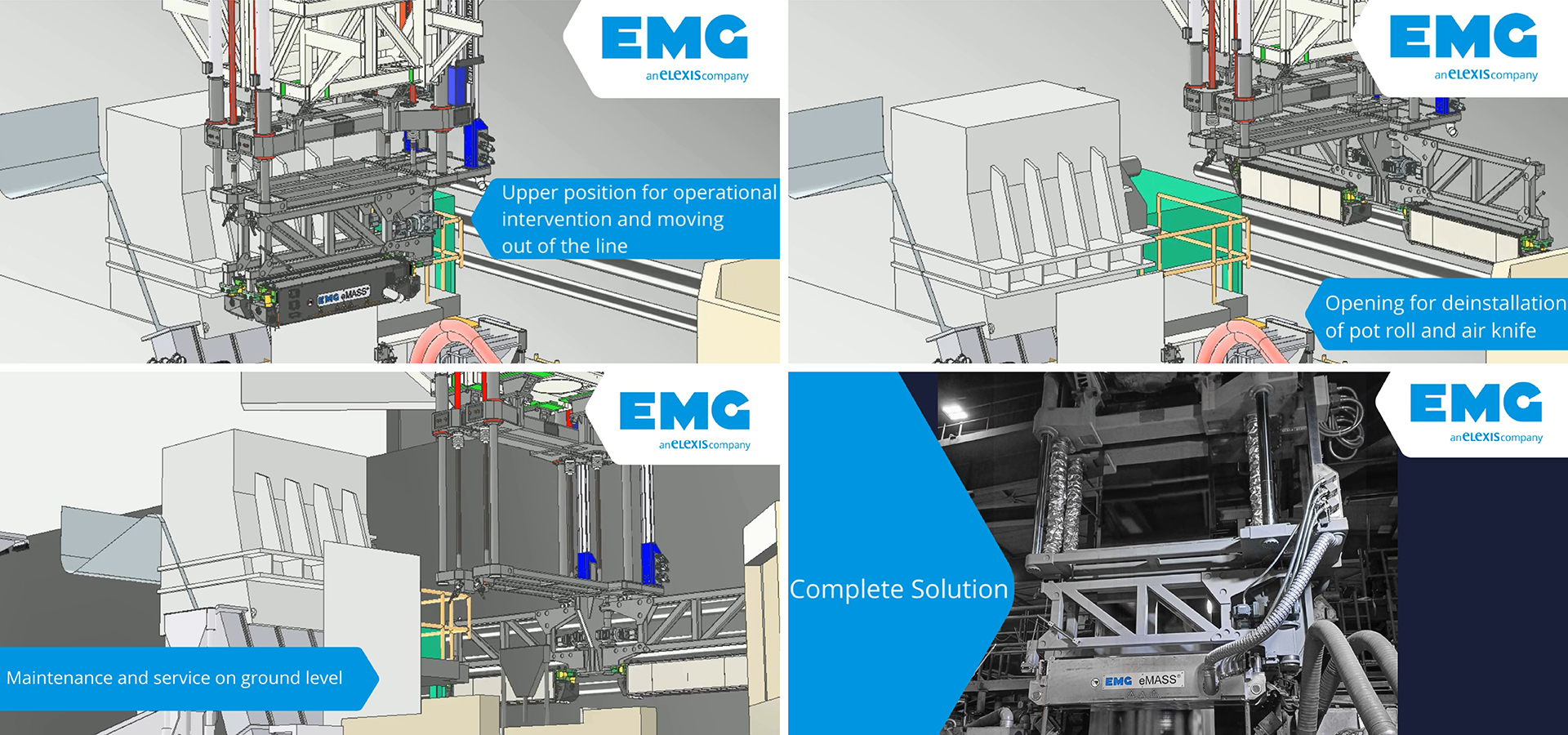

Due to the limited space available, the EMG eMASS® system was installed underneath an existing mobile pre-cooler. With a height adjustment of over 2 metres, the EMG eMASS® can be positioned close above the height-adjustable air knife, but can also be lifted to a higher position to allow access to the nozzle lips during operation if required. During regular line shutdowns, EMG eMASS® is moved out of the line in this upper position, hanging below the pre-cooler, to make room for changing the air knife assembly.

However, 3D modelling during the project planning phase showed that the movement of the large bottom roll out of the zinc bath is hindered by interfering edges of EMG eMASS®. The solution was therefore found to open up the two halves of the EMG eMASS® like butterfly wings. This is also the only way to lower the system into a maintenance position close to the ground.

This makes this design unique and heavy in the truest sense of the word. The total weight are impressive 8 tonnes.

For a better understanding, please watch this video on "YouTube”: EMG eMASS® Special Application.

Of course, this is not an invitation to freely design complex integration solutions, but it demonstrates the efficiency of the EMG design and service team in an impressive way. This reflects EMG's commitment to customer-orientation in all situations. The team from the Metals business unit finds a practicable and economically viable solution even for complicated tasks.

Conclusion

In the majority of cases, EMG eMASS® can be integrated into existing air knife solutions without too much design effort and using established standard solutions. Either via a suitable separate support structure on the factory floor or via a direct mechanical coupling with the air knife construction. The ideal solution is the so-called "integrated solution" in combination with DUMA-BANDZINK air knives, which can be considered for new buildings or new air knife investments. You can find out more about this solution here!

Curious?

Would you like to know more about EMG eMASS® and the associated application options?

Please feel free to contact our sales department, our international sales organisation or our product manager Steffen Dombrowski (steffen.dombrowski@emg-automation.com) directly at any time. We look forward to hearing from you!

Video: EMG eMASS® Special Application

Download: Further information can also be found in the EMG eMASS® brochure.