Non-contact protection for the strip edges

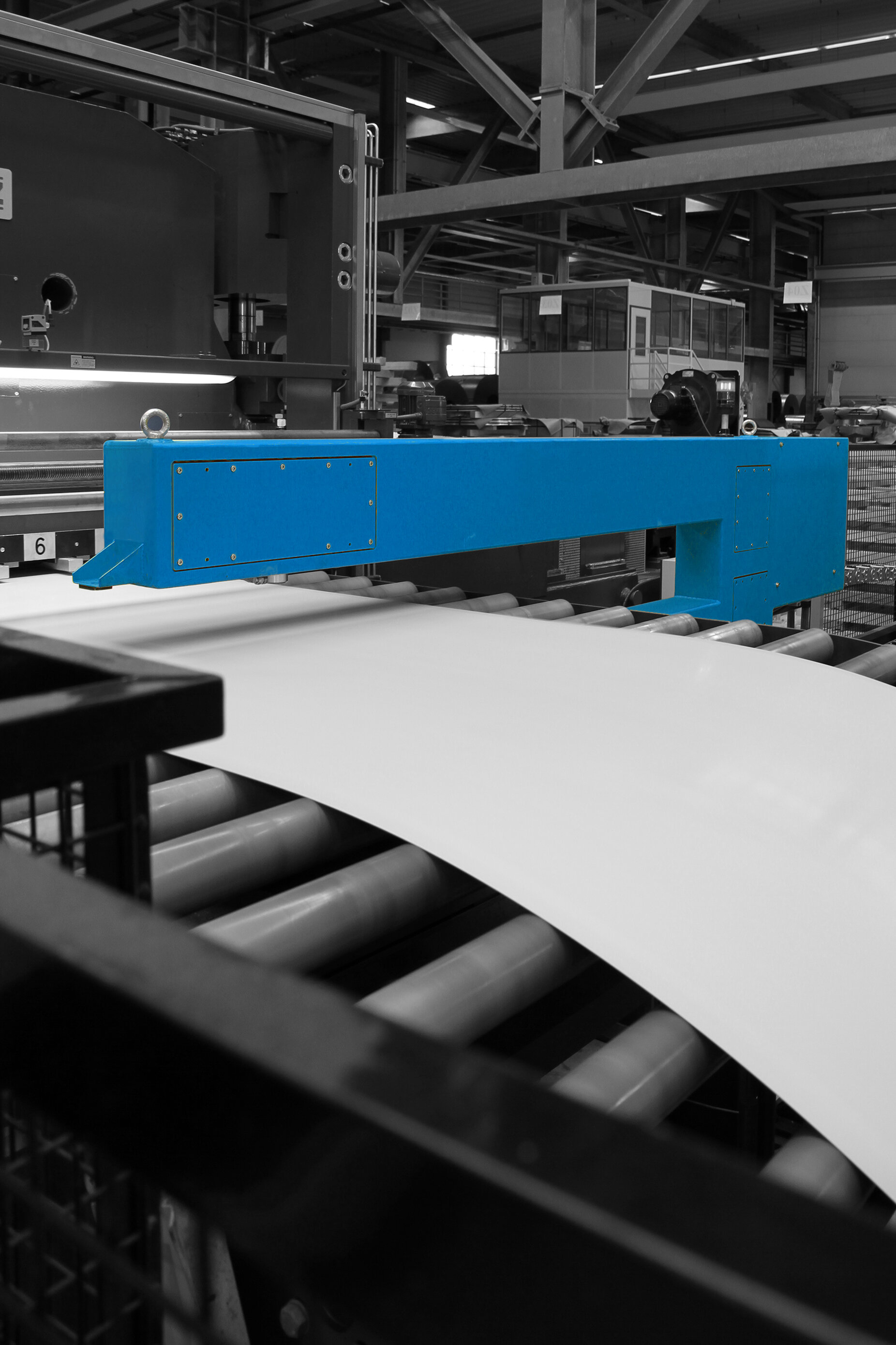

In hot-dip galvanising lines, the thickness of the zinc layer on the metal strip is adjusted with the help of compressed air-driven blow-off nozzles - so-called air knives - directly above the zinc pot. In this area, the continuous metal strip is widened by so-called "baffle blades". The aim of using baffle blades is to avoid air turbulence in the area of the strip edge and to prevent possible damage.

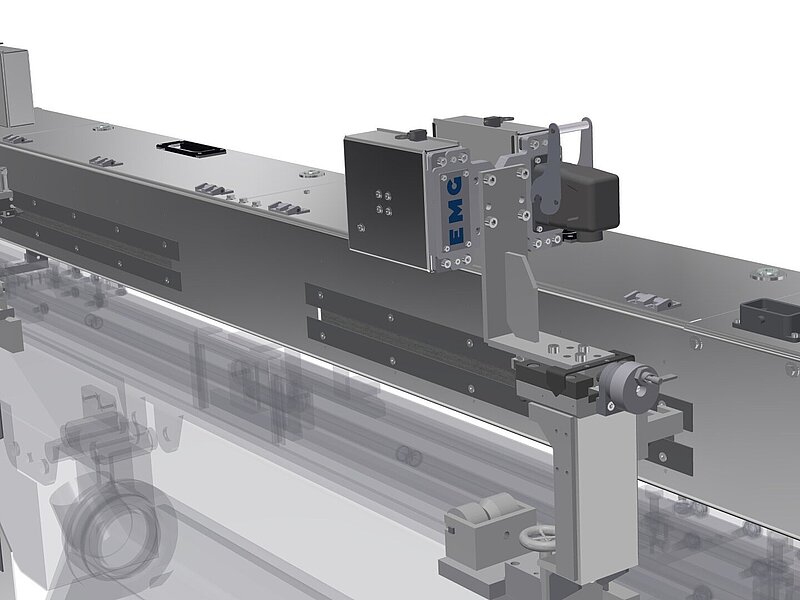

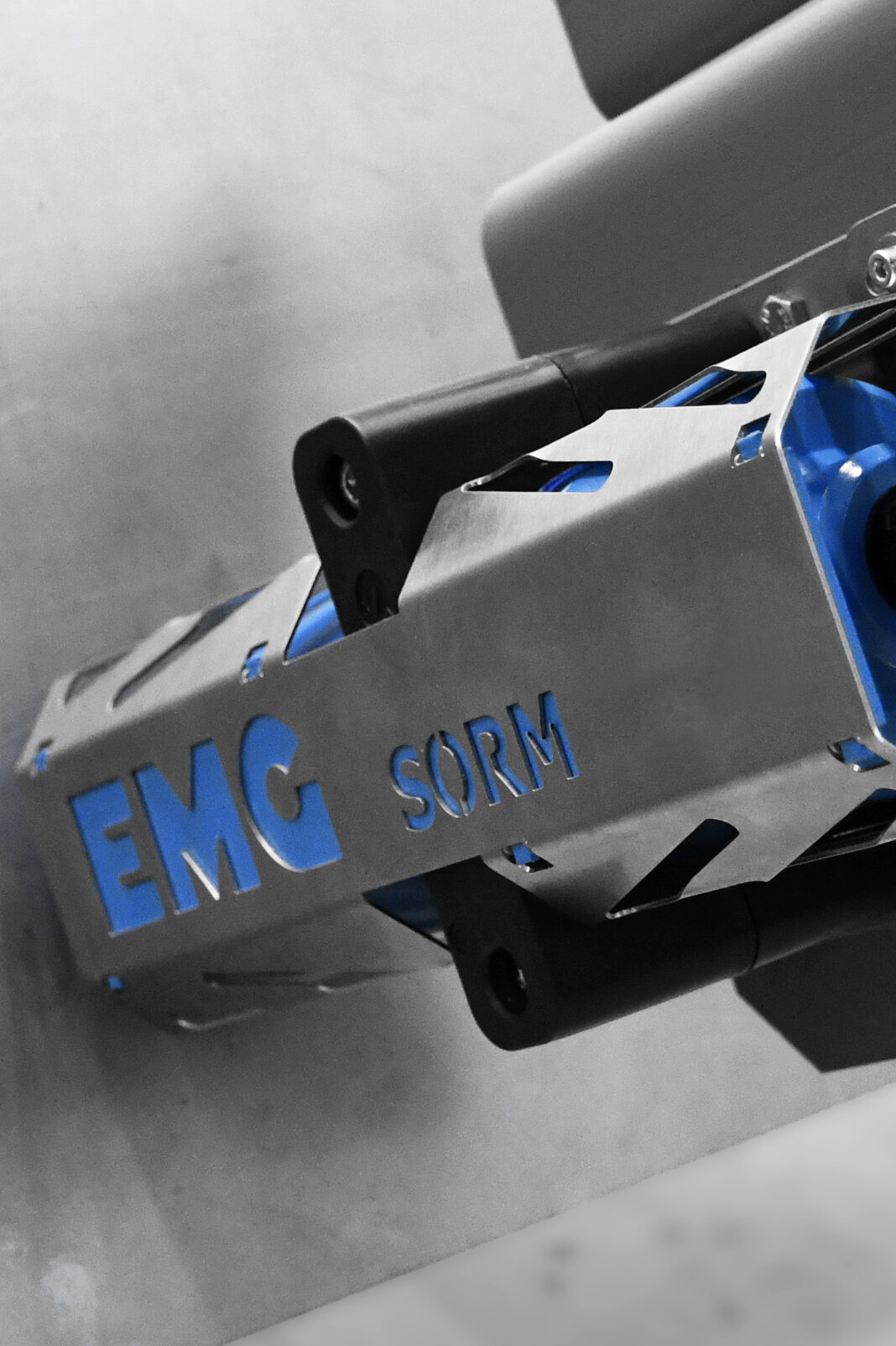

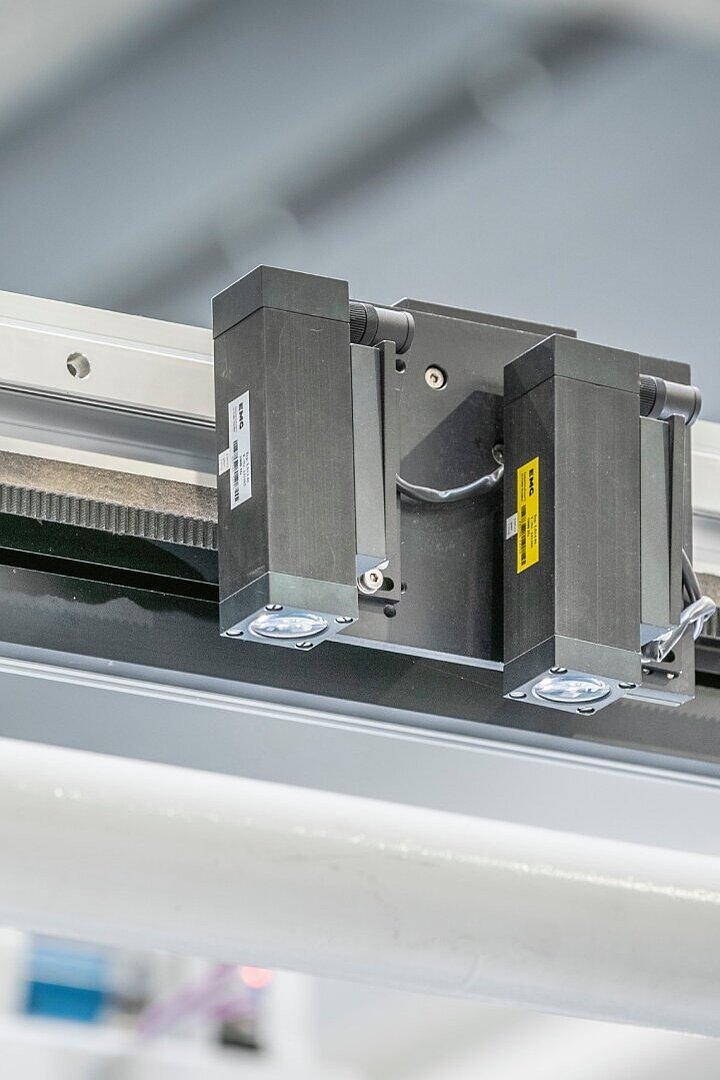

In this type of application, the baffle blades must continuously follow the edges of the strip, whose position changes due to the swarming of the strip or due to changes in the strip width. Our EMG eBACS inductive edge sensors enable highly accurate, non-contact tracking of the baffle blades. In this way, they avoid damage to the edges of the strip, which would be caused by zinc flaking off or by the mechanical contact of touch rolls.

Have we caught your interest? Get in touch!

"Only in intensive discussion with technologists and line operators is it possible to gain an understanding of the special features of the production processes supported by EMG's quality assurance systems. This is what EMG stands for with its long-standing market presence. Thus, with the EMG eMASS® strip stabilisation, demonstrable improvements in quality and zinc consumption are possible in the hot-dip coating of steel sheets."

Steffen Dombrowski, Product Manager

More solutions

In the production of steel and aluminium strips, the increased demands on new materials and ever more complex components require an increasingly higher level of process reliability. With our innovative quality assurance systems for the cold rolling area, you can optimise your processes - and thus also your product quality. All EMG systems are based on the same hardware and software structure. Benefit from the use of our broad solution portfolio and reduce your TCO (Total Cost of Ownership).