Strip guiding systems

The high-quality strip guiding systems of our Metal business unit optimally support steel manufacturers and processors in their technological production processes. By keeping the metal strip in the centre of the line or another fixed position during processing, a uniform strip passage is created. This prevents damage to the product or the production plant.

Quality assurance systems

Increasing demands on new materials and ever more complex components require optimisation of process safety in the production of steel strips. Our innovative quality assurance systems offer you every opportunity to continuously improve your manufacturing processes and increase your production quality.

Crane systems in iron and steel works

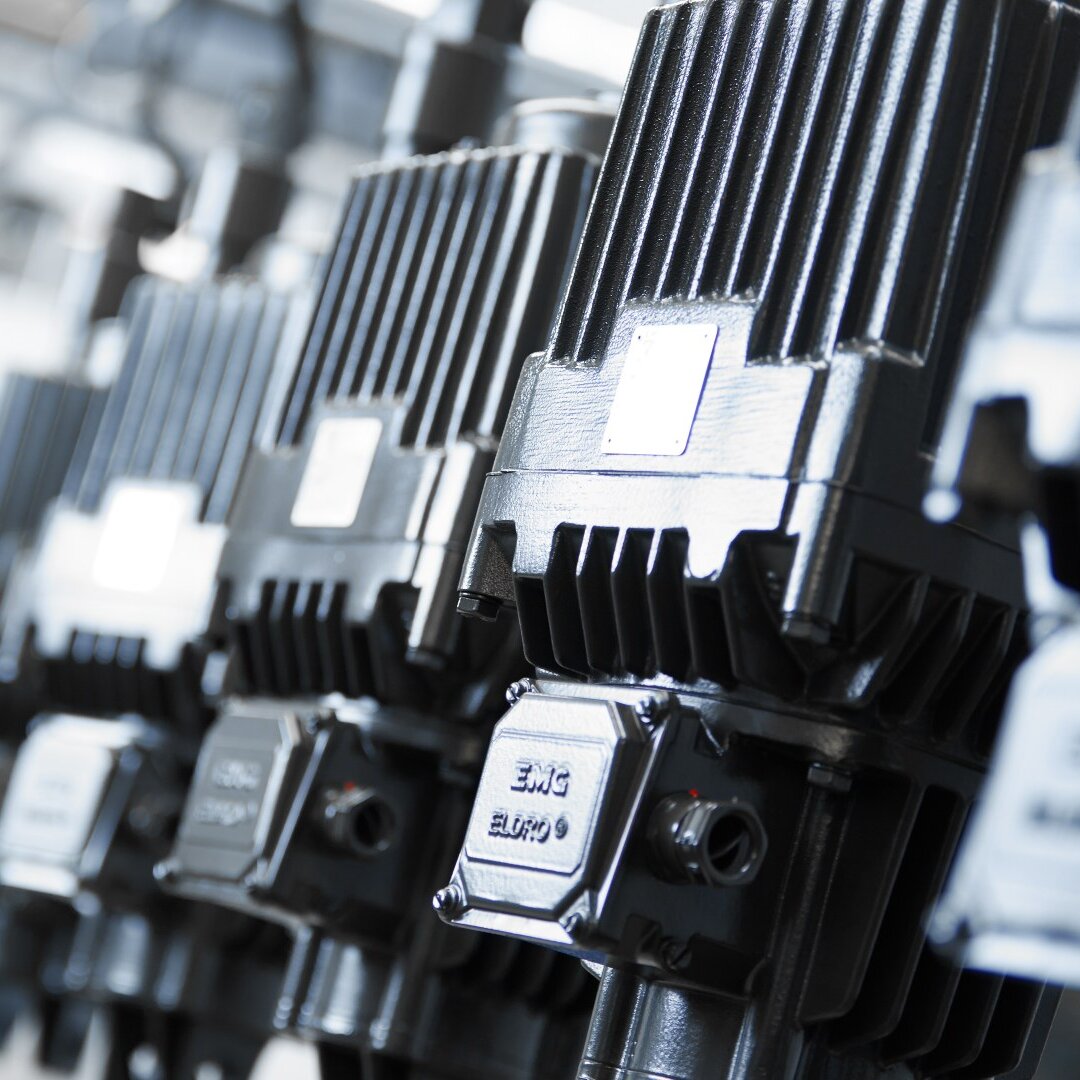

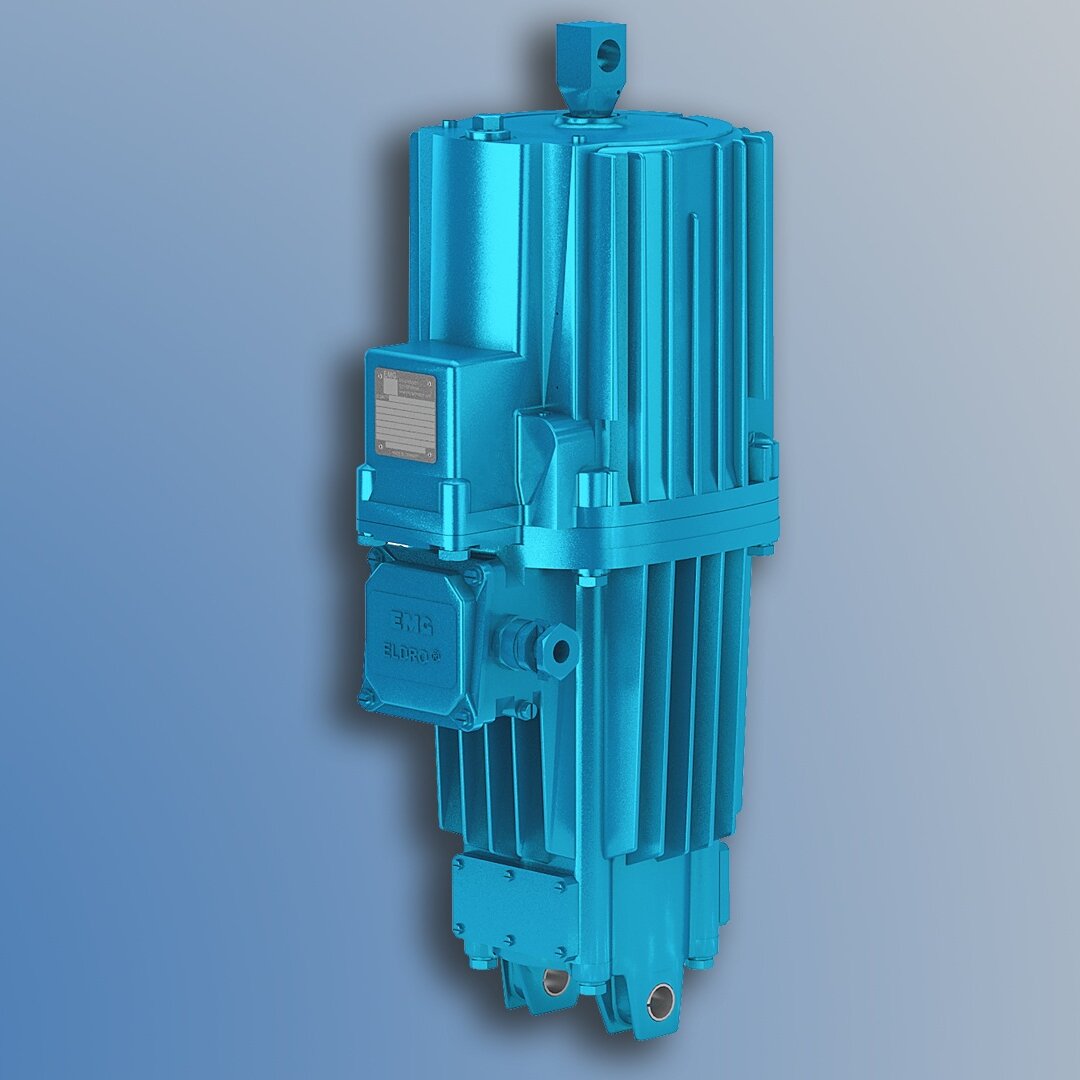

Crane systems are important equipment in production processes; their continuous operation guarantees the quality of the end products to a large extent. Although high ambient temperatures, extreme lifting loads or aggressive dusts often make operation difficult, the safety and availability of the systems have the highest priority and do not tolerate any compromises.

That's why steel producers all over the world trust the quality of EMG ELDRO® and EMG ELHY® brake releases from our safety components for heavy duty logistics ELDRO® & ELHY® business unit. "Made in Germany", these EMG quality products guarantee perfect functioning of the electrohydraulic drum or disc brakes even under the highest stress and load. For man and machine, this means the greatest possible safety.

Have we caught your interest? Get in touch!

"We offer our customers complete solutions for their individual requirements - you describe your problems and we work out the appropriate solution. We plan, we advise and we accompany our customers until the complete commissioning! From the first contact to the finished technical clarification, your request is in one hand with EMG!"

Jochen Fryn, Head of European Sales

Please contact me:

T: +49 2762 612-212

E-Mail: jochen.fryn@emg-automation.com