This is how you optimise your oiling and pressing process

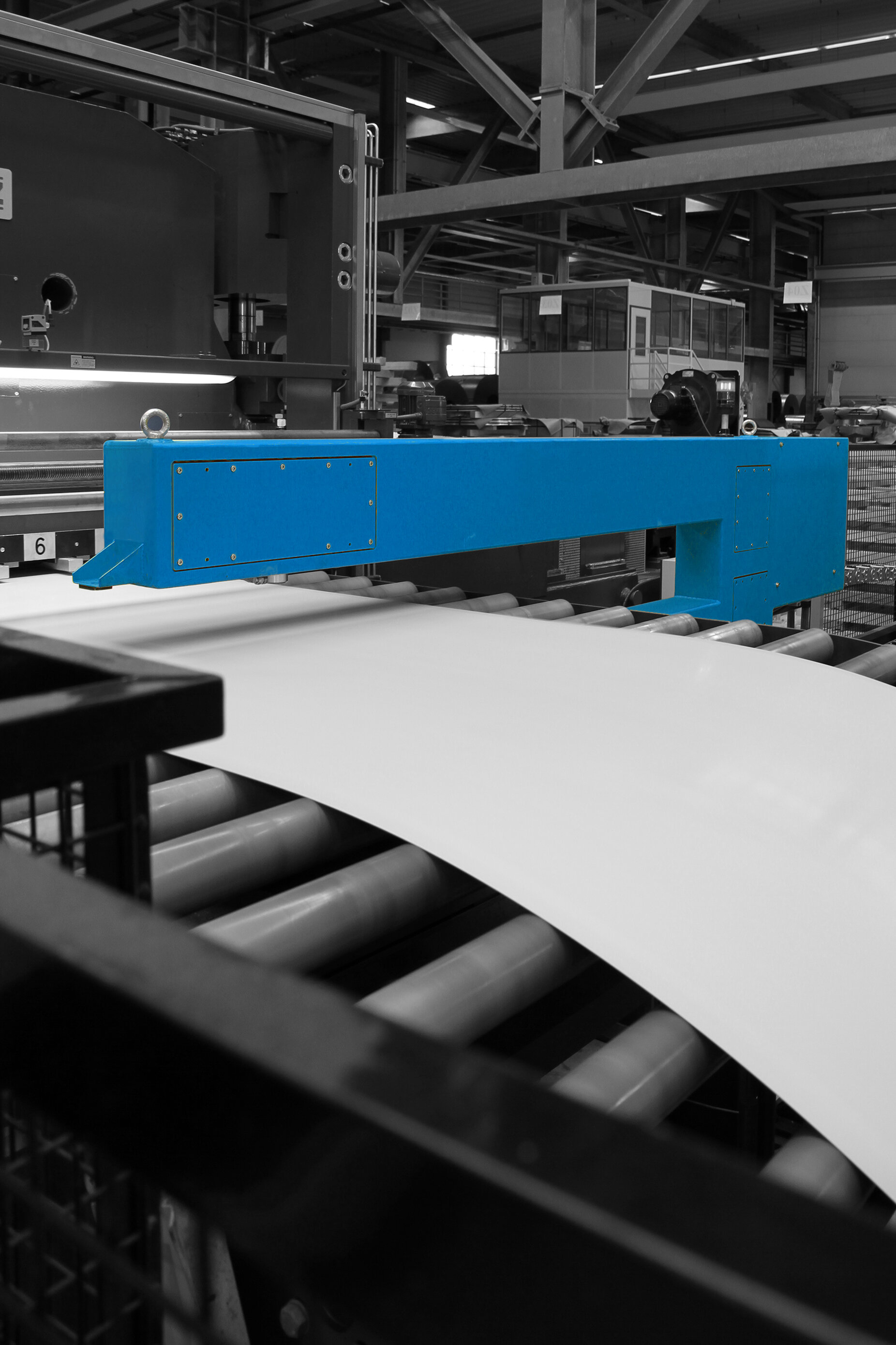

Increased demands on new materials and ever more complex components increasingly require higher process reliability. This also applies with regard to the oil coating for the forming process of steel and aluminium sheets. EMG SOLID® is a system for the up-to-date online measurement of oil deposits on running strips.

Especially in the automotive industry, the requirements for a uniform, defined lubricant application are becoming ever higher. EMG SOLID® offers a wide range of applications: from initial oiling in the rolling mill to the metal processor, for whom sufficient oiling during the shaping process or freedom from oil before painting measures are indispensable.

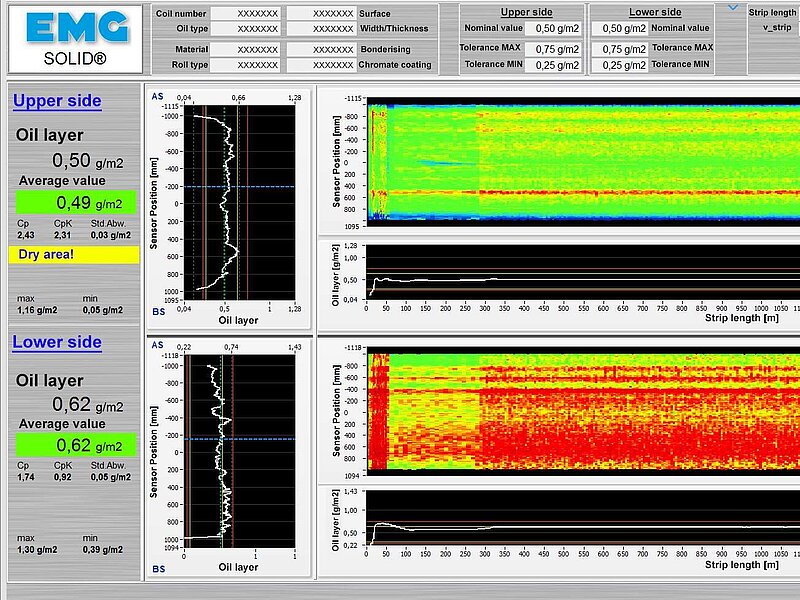

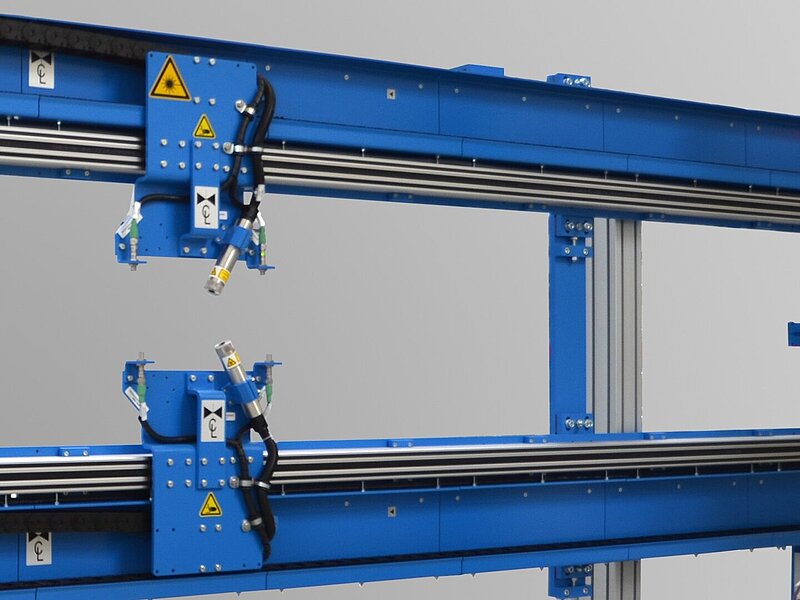

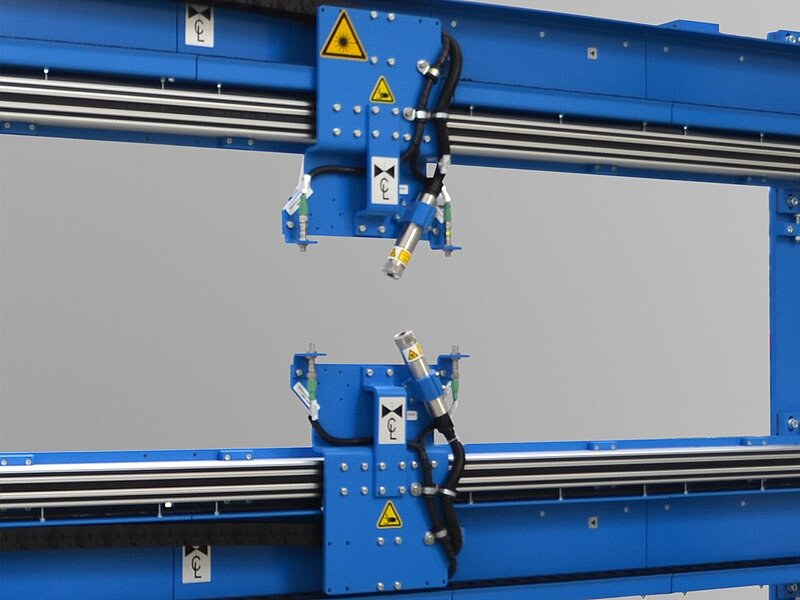

EMG SOLID® measures the oil layer within the production line online over the complete width and length and visualises it over the entire surface to be measured.

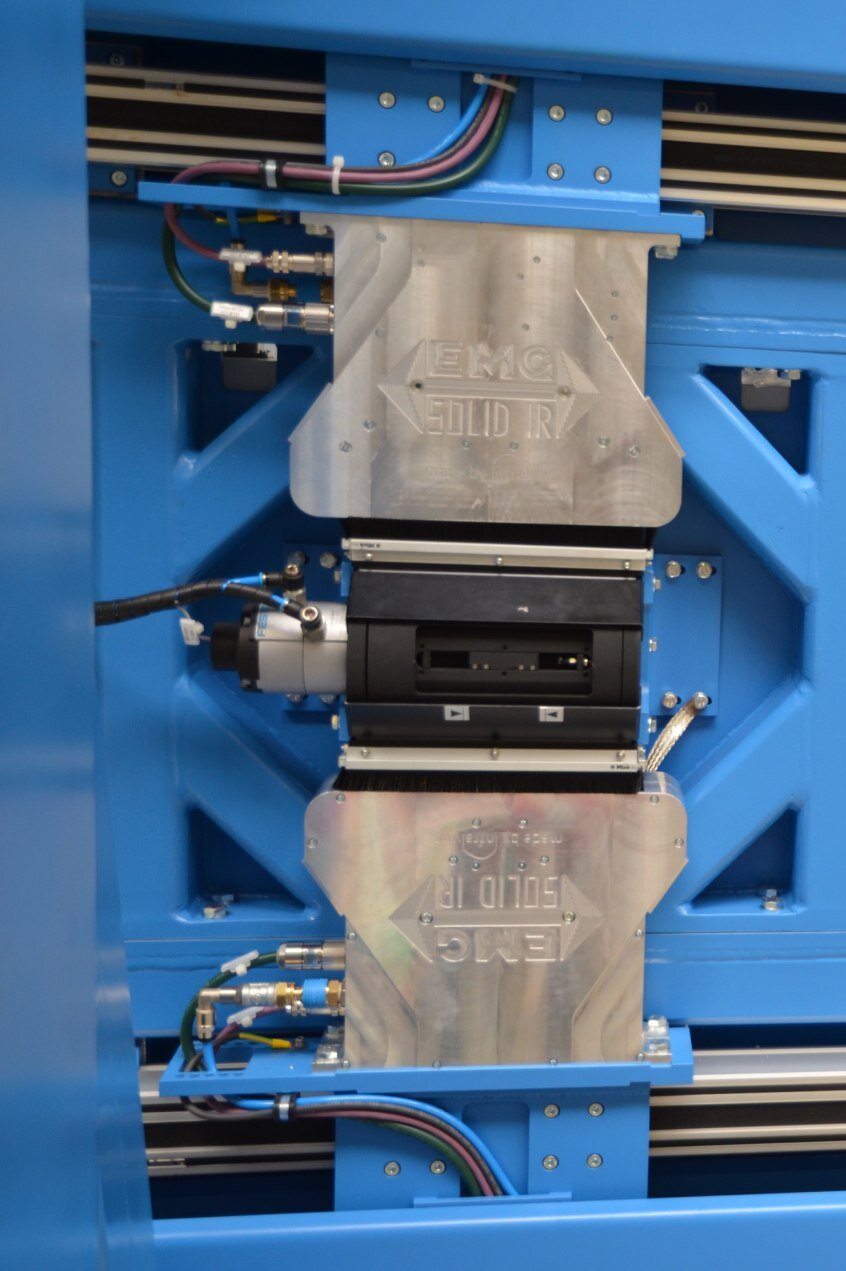

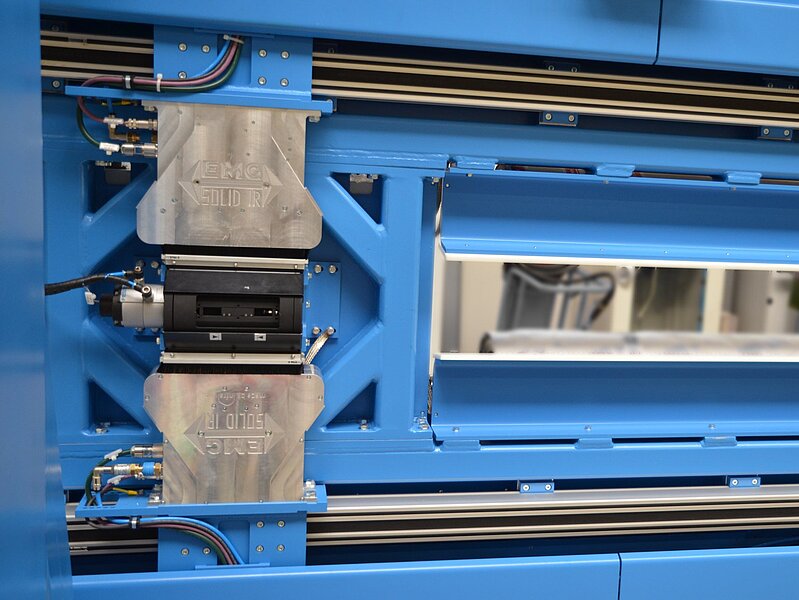

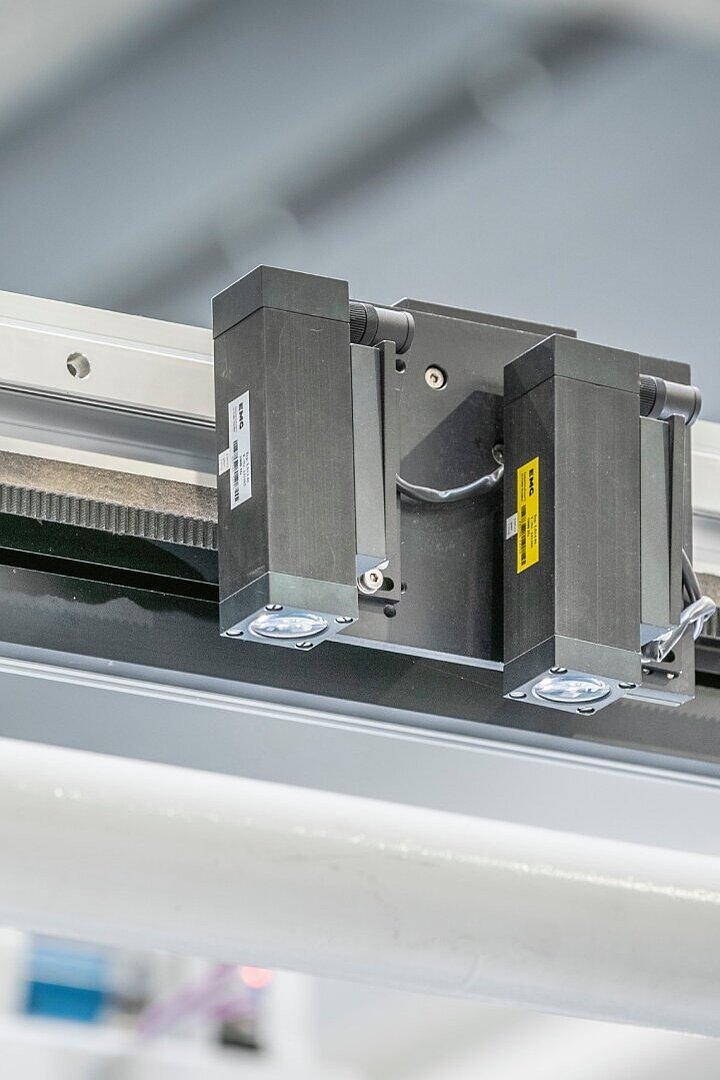

EMG SOLID® IR

Our solution EMG SOLID® IR uses the technology of infrared spectroscopy. The system generates an infrared light that penetrates the oil layer, is reflected by the strip surface and penetrates the oil layer again. In the process, the intensity of specific wavelengths is attenuated by the oil layer: the thicker the oil layer, the less light is reflected.

EMG SOLID® IR then calculates the layer thickness of the oil layer according to Lambert-Beer's law.

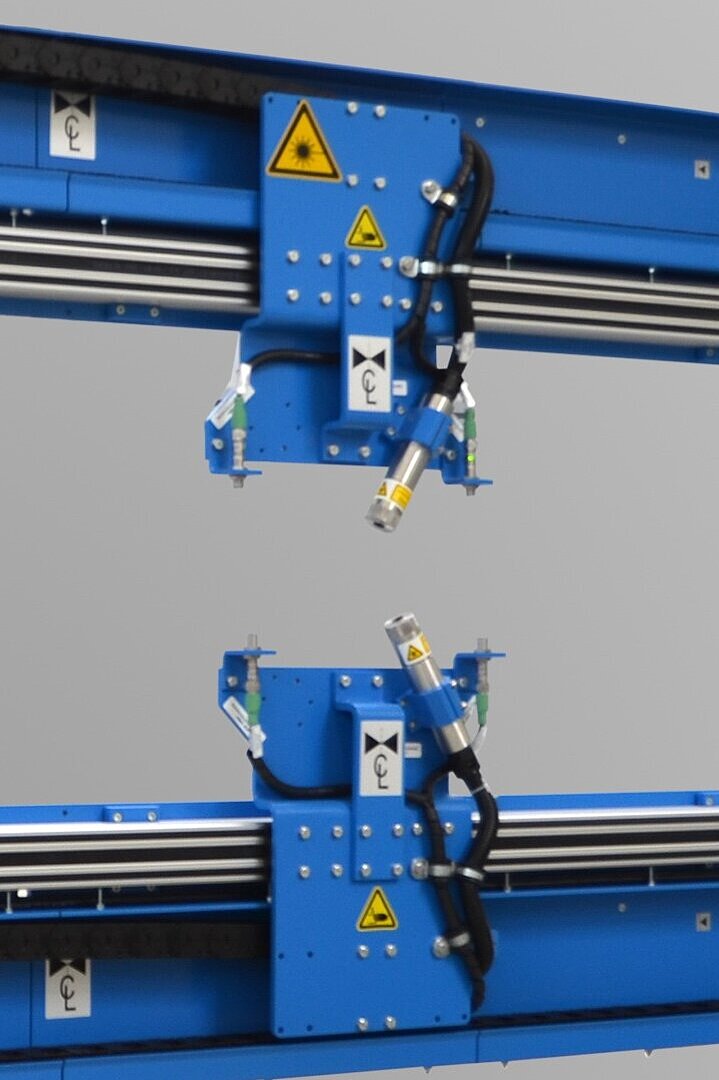

EMG SOLID® LIF

Using laser-induced fluorescence spectroscopy, the system measures the weight per unit area of the oil layer and then visualises it over the entire surface of the material. A special solid-state laser delivers 10,000 individual pulses per second, robust and flexible quartz fibre bundles transmit the light energy to the measurement location.

Via a second quartz fibre bundle, a highly sensitive photomultiplier detects individual photons of the fluorescence signal. These are recorded by a counter system with time resolution in the nanosecond range and statistically evaluated. A microcontroller then controls the analysis system; it manages the system calibrations and calculates the results.

The insulation layer - quality makes the difference

Pigment-based electrical steel coatings (core sheet slag) have two main functions. Firstly, they provide electrical insulation, which is essential to prevent leakage currents or flashovers between different layers of transformer laminations. This ensures the safe and efficient operation of electrical equipment. Secondly, these coatings form a protective layer on the surface of the electrical steel that prevents corrosion and rusting. This is important for electrical steel sheets that are often used in corrosive environments.

In addition, there is also the function of fully bonding laminations with so-called baking enamels. In this process, a paint that is not fully cured is applied to the surface of the electrical steel, which is then cured at high temperatures to create a permanent bond between the various laminations. This reduces the losses associated with eddy currents and hysteresis, which can lead to heating and wasted energy.

Determining the layer thickness of the insulating varnish and its change or deviation from specified values over the entire strip length is therefore a quality feature that has a decisive influence on the manufacturer's profitability.

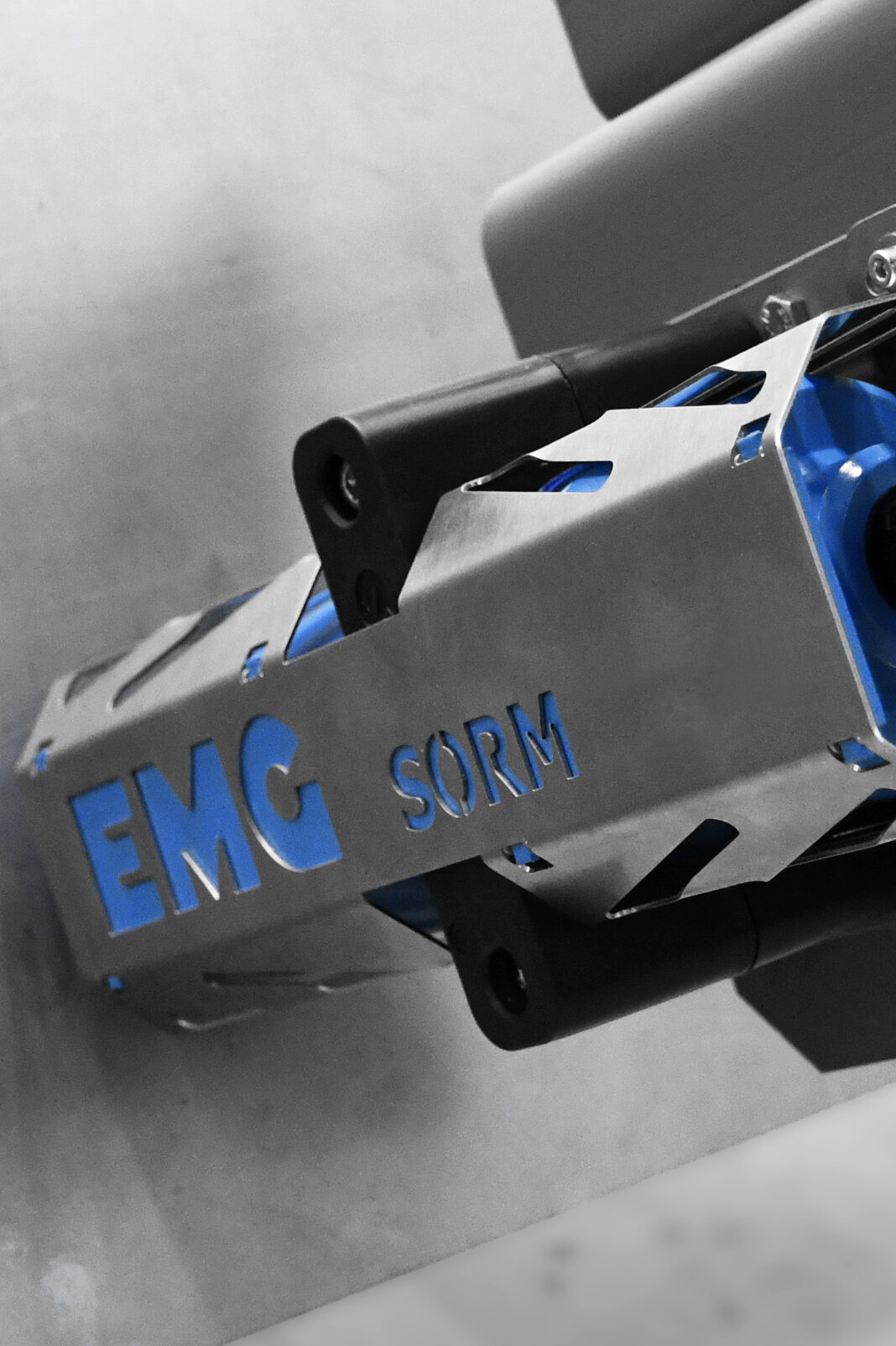

EMG SOLID® DFT (Dry Film Thickness) controls this layer thickness with the help of laser-induced fluorescence spectroscopy.

EMG SOLID® DFT

EMG SOLID® DFT (Dry Film Thickness) measures the coating weight of the transparent and low pigmented lacquer layer via laser-induced fluorescence spectroscopy and visualises it over the entire measured material surface:

- Special solid state laser delivers 10.000 single pulses per second and stimulates the lacquer to glow.

- The more lacquer lies on the material surface, the stronger the glowing effect.

- A micro controller controls the analysing system, manages the system calibrations and calculates the results.

Have we caught your interest? Get in touch!

"Our product family for online oil layer measurement EMG SOLID® is based on two technologies: Infrared Spectroscopy and Laser Induced Fluorescence Spectroscopy. The use of these two technologies puts EMG in a unique position to offer our customers the optimum solution for their requirements. We are happy to advise you, please contact us!"

Timo Gemmer, Product Manager

Pleas contact me:

T: +49 2762 612-349

E-Mail: timo.gemmer@emg-automation.com

More solutions

In the production of steel and aluminium strips, the increased demands on new materials and ever more complex components require an increasingly higher level of process reliability. With our innovative quality assurance systems for the cold rolling area, you can optimise your processes - and thus also your product quality. All EMG systems are based on the same hardware and software structure. Benefit from the use of our broad solution portfolio and reduce your TCO (Total Cost of Ownership).