System design

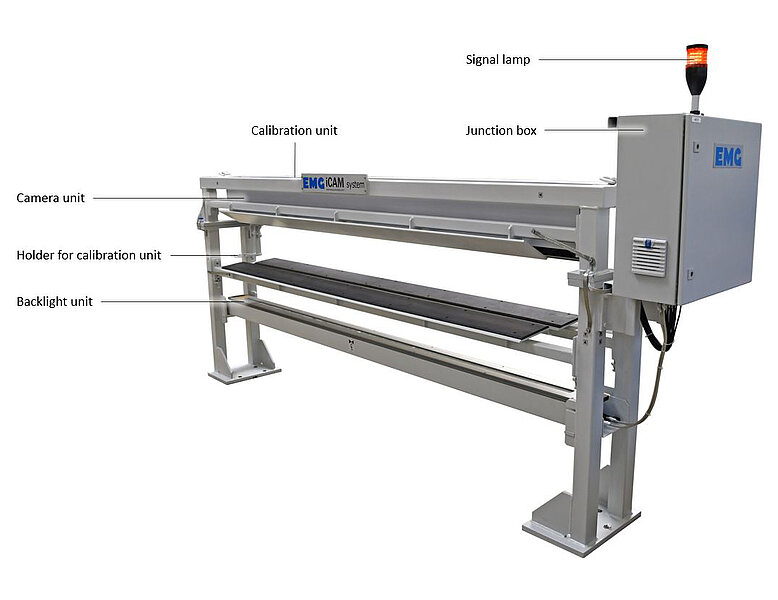

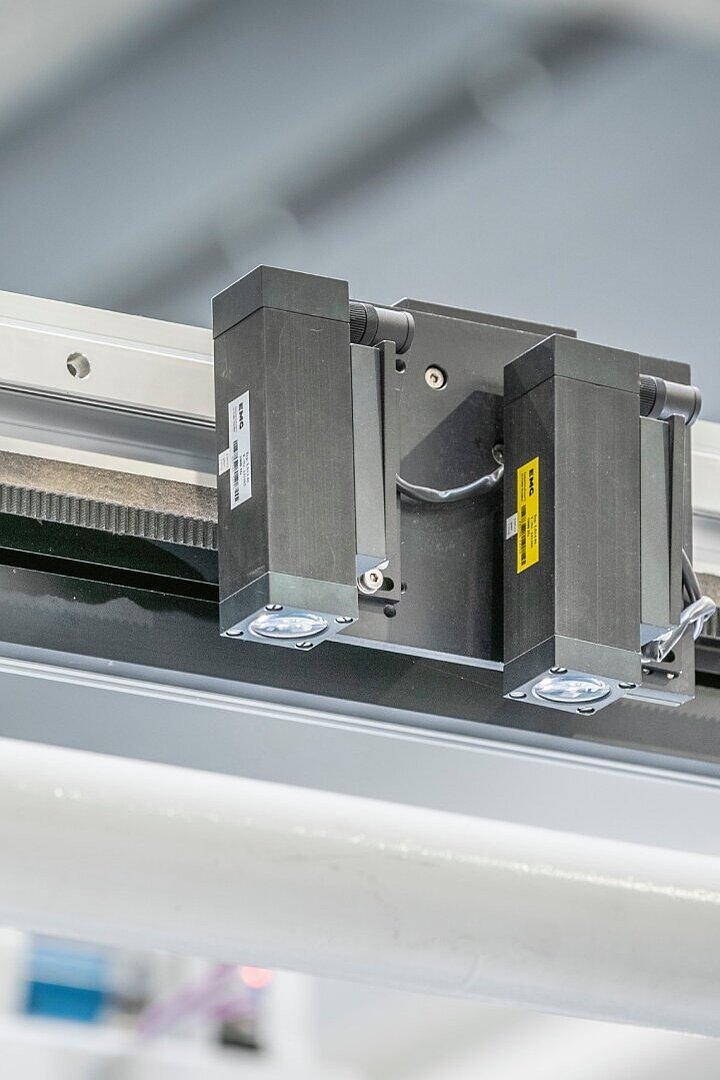

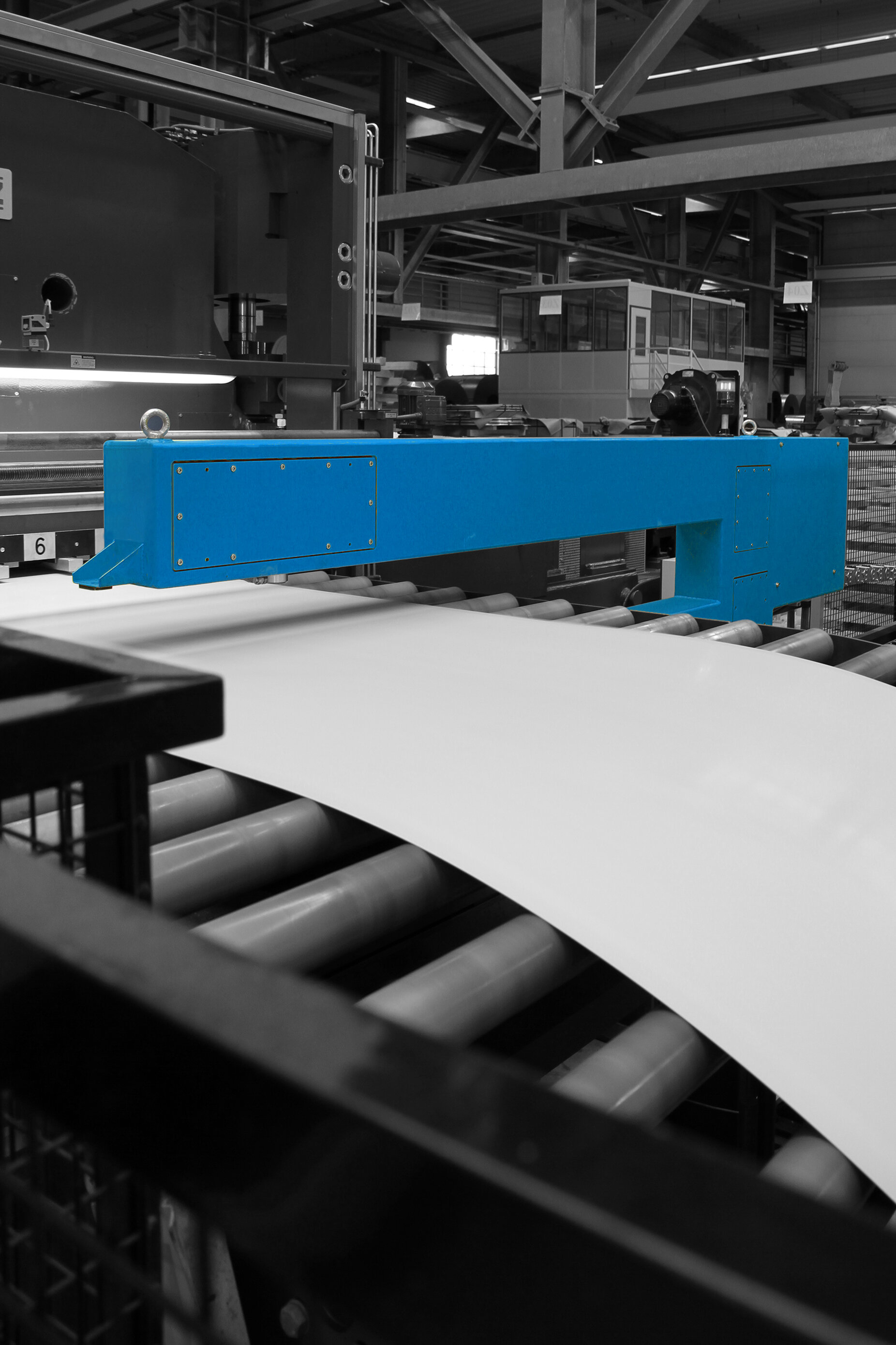

The EMG iCAM® system consists of an LED backlight unit ("emitter unit") below the metal strip and a camera unit above the strip, consisting of several CMOS cameras, as receiver unit. The standard strip width is 1,000 mm to 2,250 mm and is scalable in steps of 250 mm (other strip widths on request).

The LED backlight unit emits infrared light in a defined spectral range in the direction of the strip. This is selected in such a way that a maximum reduction of the influence of extraneous light sources is achieved.

The light from the LED backlighting unit is shaded by the metal strip and only in the areas of the strip edges does light pass through, which is detected by the CMOS cameras. Modeled after human eyes, two adjacent cameras each capture the identical position of photons on the strip from two different directions emitted by the LED backlight unit. This measuring principle is based on the stereo vision concept.

Have we caught your interest? Get in touch!

"Nature shows us every second how detailed and precise we perceive our surroundings with our eyes in perspective.

Nature meets Technology - EMG iCAM® captures details precisely every second. Let us implement the best solution for you TOGETHER from your challenge and our technology. Technology meets Industry!"

Mathias Klein, Product Manager

Please contact me:

T: +49 2762 612-158

E-Mail: mathias.klein@emg-automation.com

More solutions

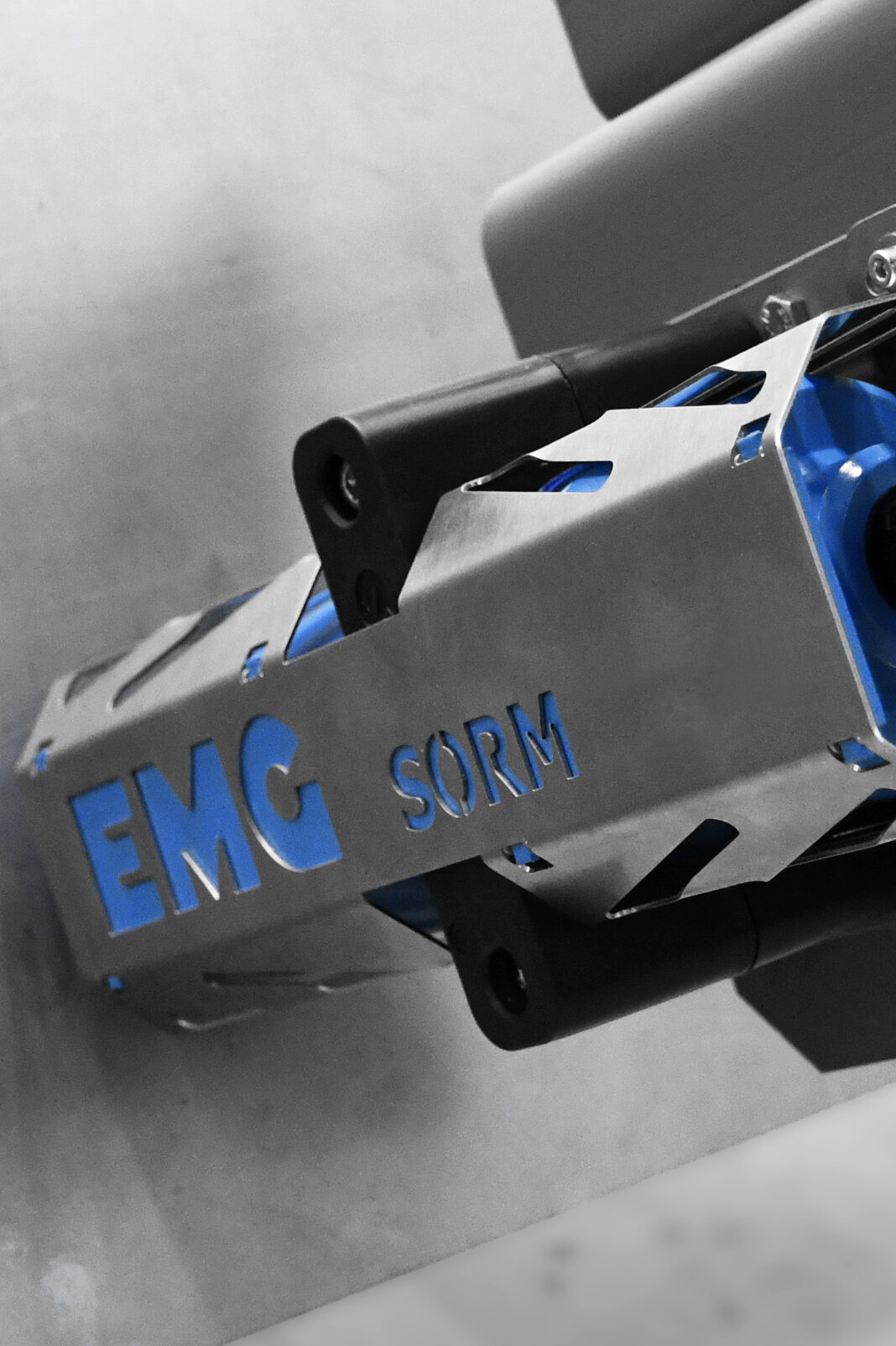

In the production of steel and aluminium strips, the increased demands on new materials and ever more complex components require an increasingly higher level of process reliability. With our innovative quality assurance systems for the cold rolling area, you can optimise your processes - and thus also your product quality. All EMG systems are based on the same hardware and software structure. Benefit from the use of our broad solution portfolio and reduce your TCO (Total Cost of Ownership).