EMG hotCAM -

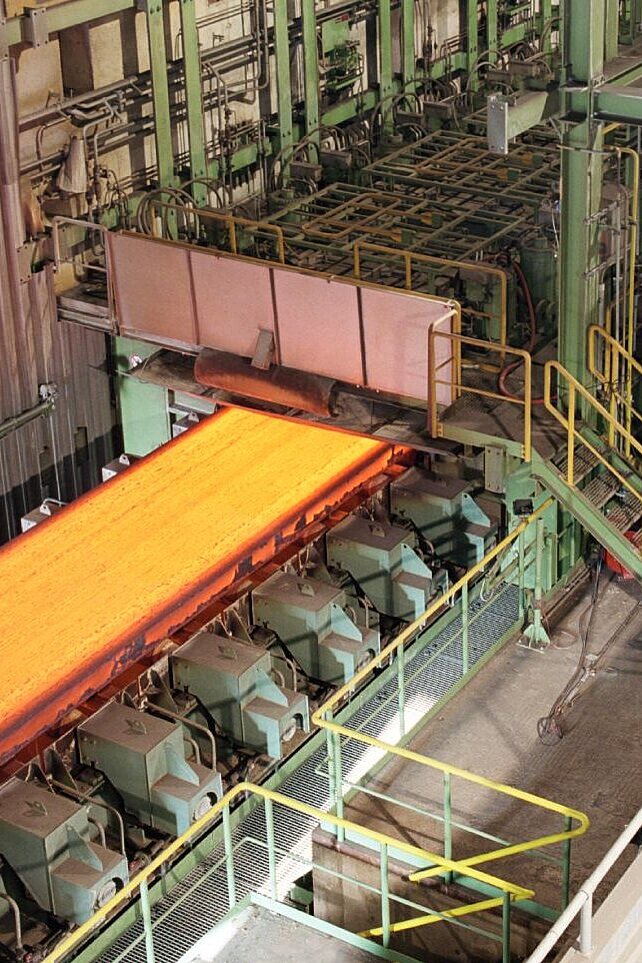

Optical strip position measurement in the hot rolling stand

The hot rolling process is typically a combination of a reversing stand (roughing stand) and a finishing line with several rolling stands. Maintaining a defined position of the strip between the rolling stands is essential for process safety in a hot rolling mill. Continuous measurement of the strip position with our EMG hotCAM solution enables you to optimise the adjustment of the rolling force and gap.

In reversing stands this leads to a reduction of the camber of the strip and thus prevents collisions of the strip with the mechanical strip guiding rail. Continuous control of the centre position in a finishing line also reduces strip guiding cobbles, which could otherwise result in serious damage and interruptions to the production process.

How to realise a closed-loop control for hot mills with EMG hotCAM

There are different ways to realise a control with EMG hotCAM. One possibility is the development of an automation solution on the user side.

The solution significantly supported and preferred by EMG, which has already been successfully implemented several times worldwide, is the use of EMG hotCAM in the automation environment X-Pact® of the SMS group. The embedding of EMG hotCAM in the SMS group's X-PactSense® family, which took place in 2021, ensures that the realisation of such a control concept will be possible via this route both for customers of the SMS group and for users without previous use of the SMS automation environment.

Have we caught your interest? Get in touch!

"Our strength lies in the fact that we define and solve tasks together with the customer. The intensive exchange brings positive effects for the successful implementation of joint projects. For example, together with our customers we were able to develop a control algorithm based on the measurement results of EMG hotCAM, which enables automated control of the rolling mill."

Guido Eichert, Product Manager

Please contact me:

T: +49 2762 612-263

E-Mail: guido.eichert@emg-automation.com

More solutions

This also applies to the hot area: Special conditions require special solutions. Learn more about the possibilities and advantages of the EMG solution EMG iSCAN®: Slab dimension measurement, positioning and tracking to optimise your hot rolling processes.

All EMG systems are based on the same hardware and software structure. Benefit from the use of our broad solution portfolio and reduce your TCO (Total Cost of Ownership)!