Background

With more than 70 installations worldwide, the EMG IMPOC magnetic inductive measuring system for the material properties tensile strength and yield strength is the only industrially established and operationally reliable measuring system for non-contact online material testing of ferromagnetic flat steel. The system is mainly used on hot-dip galvanising and annealing lines and increasingly on pickling lines in steel production, but also on pressing and stamping lines in the automotive industry.

EMG IMPOC uses an indirect measurement method that correlates the magnetic properties of the steel with results from destructive testing and develops mathematical models based on this. With the help of these models, a very good determination of the tensile strength and yield strength of the material under investigation can be made from the measured value (gradient of the residual magnetic field strength). EMG IMPOC thus provides reliable results on the material properties of the rolled material directly online in production.

The models created so far for the use of EMG IMPOC cover a wide range of materials including high-strength steels of the latest generation (currently up to the order of approx. 1,200 MPa for tensile strength). EMG offers all necessary services for this system, the know-how transfer and all required preliminary investigations within the scope of an individual investment project.

Use at production lines

Looking at the type of production lines for the application of EMG IMPOC, a good 60 % of the cases are hot-dip galvanising lines, about 20 % are annealing lines, just under 10 % are pickling lines (both push pickling and continuous pickling), and finishing lines for the remaining 10 %.

If one analyses the use of hot-dip coating lines in a little more detail, a whole range of different value-adding factors come to mind. The essential ones are:

- Reduction of destructive tests

- Reduction of material losses and downgrading

- Reduction of costs for the usage of inspection lines

- Reduction of unnecessary packaging operations (depending on how long it takes to get results from destructive sample testing)

Concrete calculation of the added value

The detailed calculation of line-specific value-added amounts requires a precise examination of the production process and the handling of material property values on the line in question, the associated costs - e.g., in relation to destructive testing - and the effects on the release and further processing of the material produced. EMG has developed a consulting concept and a corresponding tool for this purpose, which in a workshop (online or on-site) helps the perspective user to generate a good estimate of the possible productivity gains and cost savings.

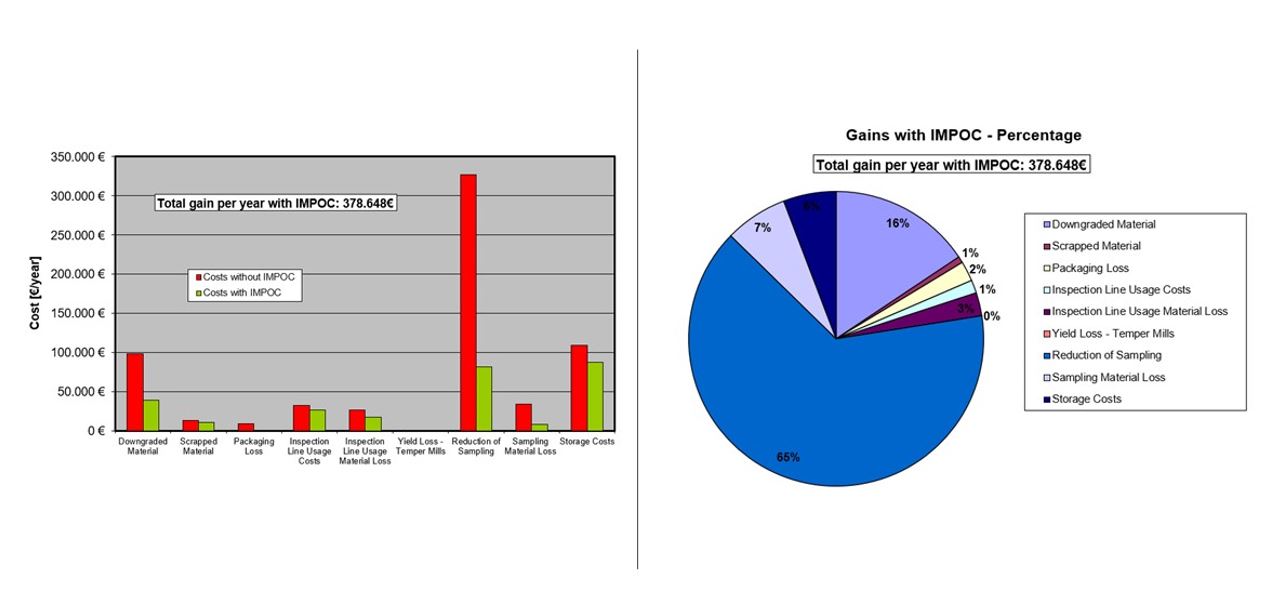

The following figure shows an example of the results for a hot-dip galvanising line with an annual production of 450,000 metric tons, 20,450 strips produced per year with an average strip width of 1,350 mm, a strip thickness of 0.8 mm and an average strip length of 2,600 m.

The potential of production gains and cost savings depends of course, besides the general production data, strongly on the actual flat steel prices and material costs, so that at this point only the order of magnitude is relevant. Typically, the annual ROI (Return of Investment) for a hot-dip galvanising line of modern design and with high quality products is above 150,000 €/a, often in the range between 250,000 and 500,000 €/a.

Conclusion

EMG IMPOC provides the end user with a proven system for reliable online measurement of the important material properties tensile strength and yield strength for a very wide range of ferromagnetic steel grades. The broad experience with the worldwide application of the system on different types of production lines is automatically available to new and existing customers of EMG. With more than 70 installations, EMG IMPOC has increasingly established itself as the quasi-standard for online measurement of strength values.

Curiosity aroused? You want to know more about EMG IMPOC and the associated application possibilities?

Please feel free to contact our sales department, our international sales organisation, or our product management (impoc@emg-automation.com) directly at any time. We look forward to hearing from you!

For further information please refer to the EMG IMPOC brochure!