Inductive Strip Centre Measurement

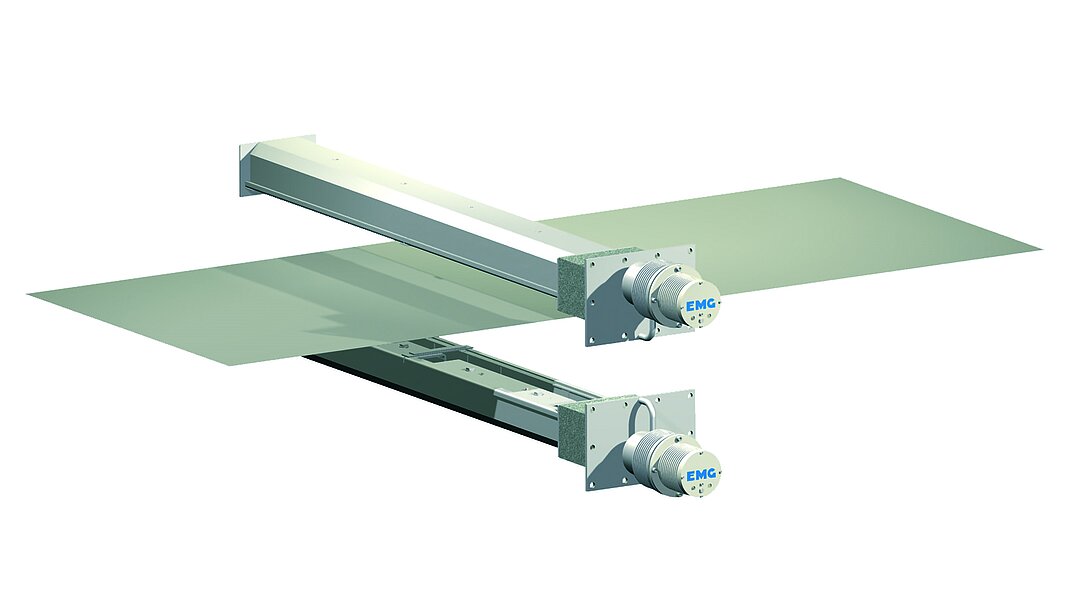

In continuous strip furnaces with horizontal or vertical strip travel and furnace temperatures up to 1,100 °C, the inductive strip center measurement monitors the strip center position with a center measurement accuracy of ±5 mm. Two temperature-resistant, tubular metal traverses with special heat-resistant coil sets run above and below the strip across the furnace. The electrical connections to the remote evaluation electronics are led out gas tight.

The system is maintenance-free, self-monitoring and contains no wearing parts. For simple installation and commissioning, all that is required is to provide a cutout in each furnace wall and to fit two double flanges in a gas-tight manner.

Have we caught your interest? Get in touch!

"The guiding of the metal strip avoids damage to your product or even the production plant. With decades of experience on our customers' strip lines, we have succeeded in perfecting the strip guiding system. With well-engineered individual components, supported by numerous sensor technologies, you put the guiding of your metal strip in good hands with EMG. Because we want to make a contribution to the quality of your products that you deserve."

Jens Kathol, Product Manager for strip guiding solutions

Please contact me:

T: +49 2762 612-405

E-Mail: jens.kathol@emg-automation.com