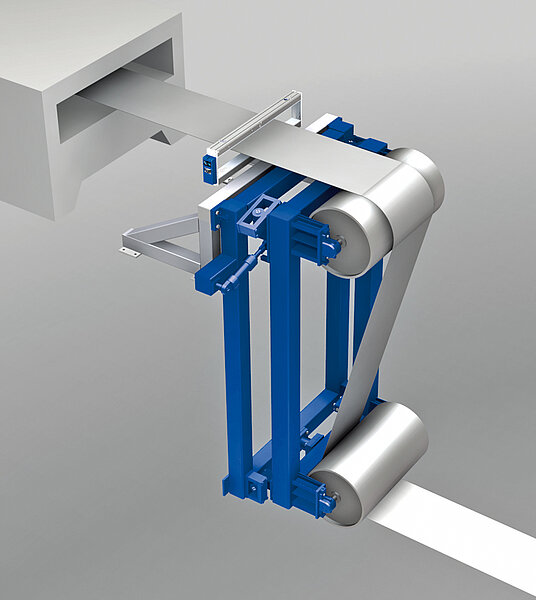

EMG SRD Guiding roll

The SRD guiding roll is used to bridge different strip heights. One possible application position for the SRD guiding roll is between the strip storage and strip processing. A major advantage of this purely proportional guiding roll type is the minimal space required by the guiding rolls. In addition, the guiding rolls have low edge stress, which means that very short infeed and outfeed distances are possible.

The guiding rolls rotate around a certain pivot point and the incoming strip section is thus shifted sideways. In the event of errors in the strip run, the guiding rolls correct the strip position in this way and return the strip to the predetermined point in the system. The strip running correction is proportional to the travel of the positioning frame. The incoming and outgoing strip forms a right angle with the swivel plane. The maximum correction capacity depends on the distance between the incoming and outgoing strip level.

Have we caught your interest? Get in touch!

"The guiding of the metal strip avoids damage to your product or even the production plant. With decades of experience on our customers' strip lines, we have succeeded in perfecting the strip guiding system. With well-engineered individual components, supported by numerous sensor technologies, you put the guiding of your metal strip in good hands with EMG. Because we want to make a contribution to the quality of your products that you deserve."

Jens Kathol, Product Manager for strip guiding solutions

Please contact me:

T: +49 2762 612-405

E-Mail: jens.kathol@emg-automation.com