Strip guiding solutions

In the production, treatment and processing of metal strips, the material delivered in material rolls - the so-called coils - is unwound and transported for processing. It is then recoiled into coils for easy transport. Due to their geometric shape, metal strips have a tendency to run to the side of the deflection rollers in the treatment lines.

The strip guiding system serves to keep a strip, which shows such tendency, in the centre of the system or in any other defined position. The strip guiding system thereby prevents damage to the product or the production plant and ensures that the strip runs evenly through the production process.

Due to increasing quality demands and very high availability with few operating and maintenance personnel, the requirements are constantly increasing. These are also reflected in the required qualities of the strip guiding systems and their components. As a rule, a strip guiding system consists of a selection of the following components:

Electronics

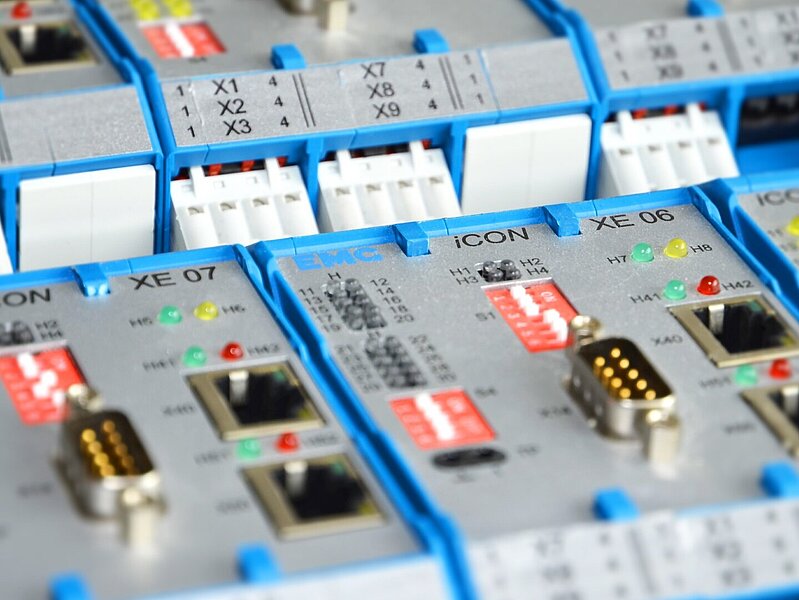

The expertise of the Metal business unit covers the entire range of modern control electronics: in-house hardware development, software programming and competent application advice for our customers. With the intelligent EMG iCON® control system, EMG offers a series for all applications including a convenient graphical HMI with touch function (EMG iCON® VS).