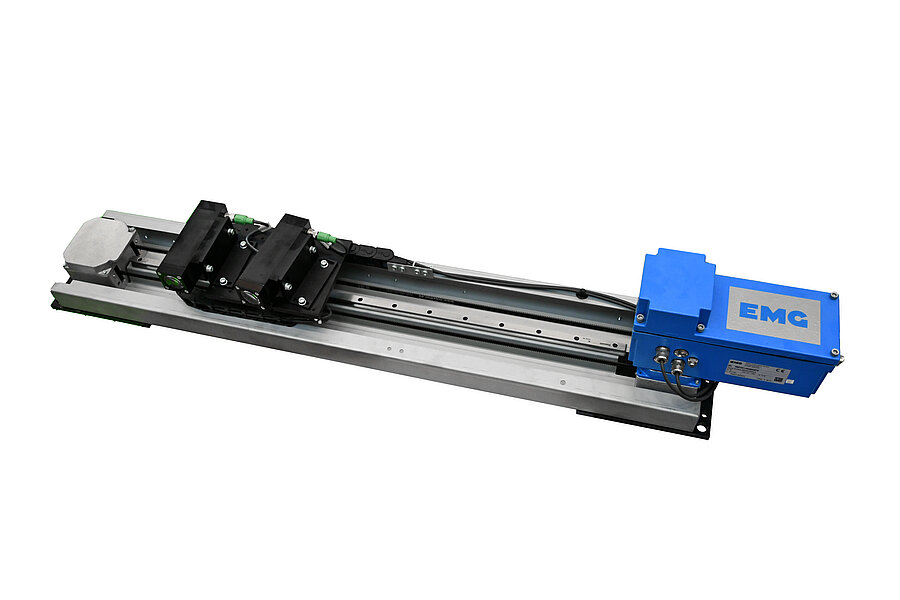

The Receiver Adjustment Device Edge EVK and the Receiver Adjustment Device Center EVM are used in the non-contact strip edge and strip center control of metal strips, respectively.Robust against external interference, EMG EVK and EVM optically detect changes in strip edge and center position.

The strip edge is optically detected by a motor-driven receiver adjustment unit, which is equipped with a light barrier that detects lateral displacement of the strip edge.

Further components of the EVK edge and EVM center receiver positioners are a linear light transmitter and an alternating light measuring receiver.

Have we caught your interest? Get in touch!

"The guiding of the metal strip avoids damage to your product or even the production plant. With decades of experience on our customers' strip lines, we have succeeded in perfecting the strip guiding system. With well-engineered individual components, supported by numerous sensor technologies, you put the guiding of your metal strip in good hands with EMG. Because we want to make a contribution to the quality of your products that you deserve."

Jens Kathol, Product Manager for strip guiding solutions

Please contact me:

T: +49 2762 612-405

E-Mail: jens.kathol@emg-automation.com