Seamless measurement of production-relevant surface parameters

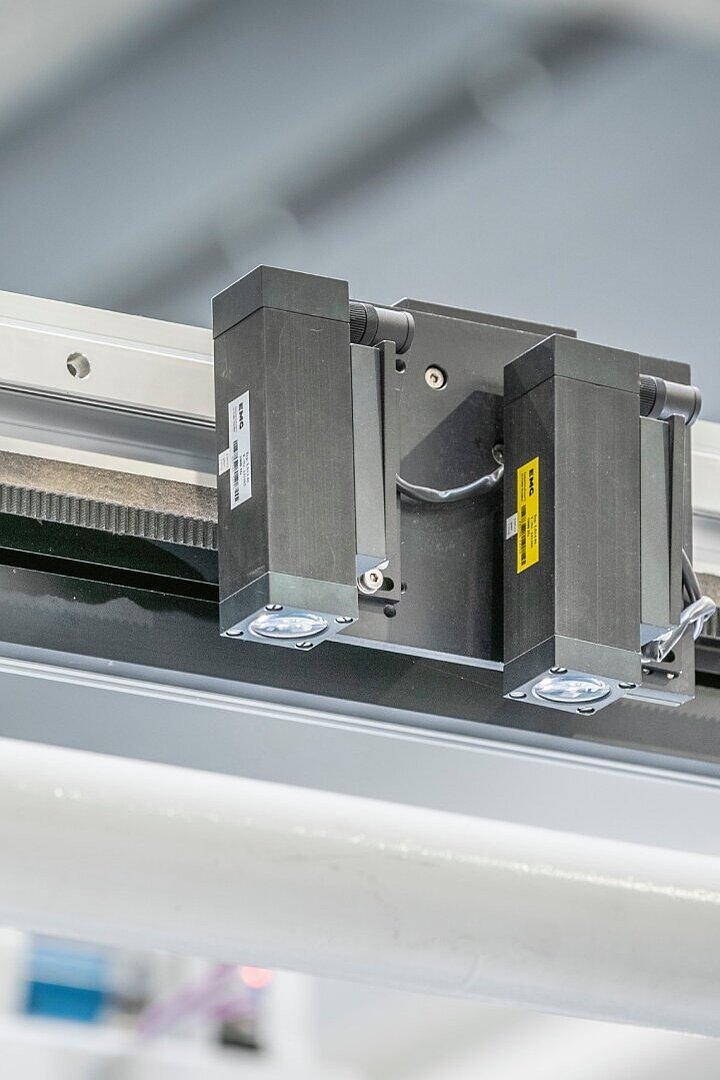

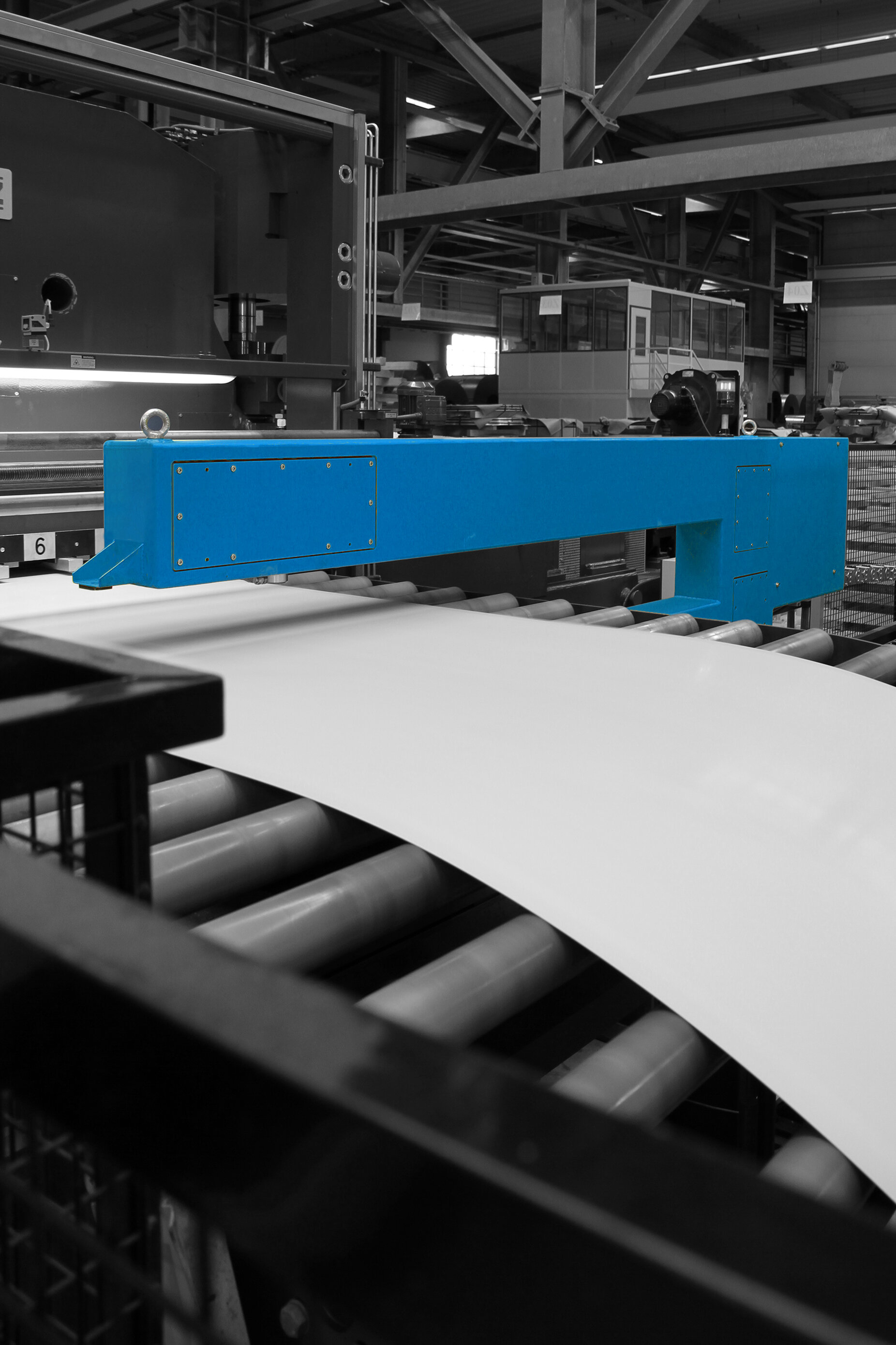

EMG SORM® is the online measuring system for recording roughness and waviness parameters on running strips. An important quality feature of uncoated and surface-finished strips are roughness characteristics. The standard method used so far is roughness measurement by means of a stylus instrument.

To do this, the operator must stop the production line or take samples from the coil and measure them offline in the laboratory. EMG SORM®, on the other hand, is a non-contact online measuring system that can be used reliably on metallic and many non-metallic surfaces.

Have we caught your interest? Get in touch!

"EMG SORM® measures the metal strip online and calculates the surface profile, from which the roughness parameters Ra and RPc as well as the waviness Wsa are then determined. Our solution thus enables the seamless measurement of production-relevant surface parameters."

Franziska Kneisel, Product Manager

Please contact me:

T: +49 2762 612-392

E-Mail: franziska.kneisel@emg-automation.com

More solutions

In the production of steel and aluminium strips, the increased demands on new materials and ever more complex components require an increasingly higher level of process reliability. With our innovative quality assurance systems for the cold rolling area, you can optimise your processes - and thus also your product quality. All EMG systems are based on the same hardware and software structure. Benefit from the use of our broad solution portfolio and reduce your TCO (Total Cost of Ownership).