Precision technology for thickness measurement

For over 60 years, customers worldwide have relied on precision technology for thickness and surface measurement from Mesacon Messelektronik. With modular system components, you can perform non-contact and non-destructive measurements during ongoing production for immediate fully automatic process control.

We offer you:

- Thickness measuring systems

- Length and speed measuring systems

- Width measuring systems

- Flatness measuring systems

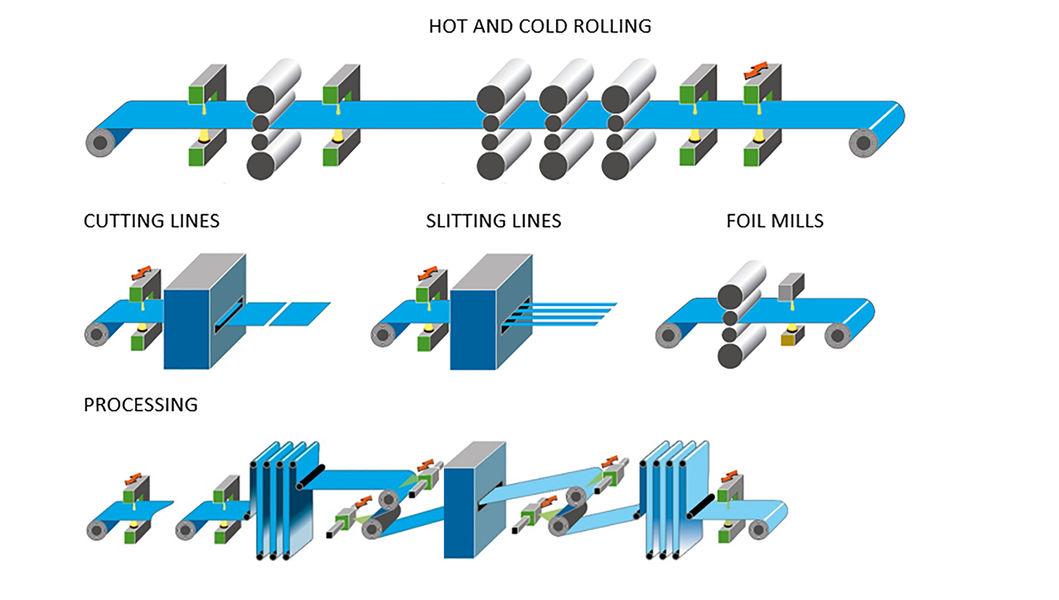

Mesacon measurement technology has proven itself worldwide in forming processes of all kinds. From wafer-thin aluminium foils to thick steel sheets, our measuring technology offers you tried and tested technologies for reliable process optimisation. In addition to standard solutions, Mesacon Messelektronik supplies individually configured measuring systems with sampling times of up to 0.2 ms to well-known producers of strip materials and plant equipment manufacturers. Thanks to these minimal response times, manufacturing processes can be monitored and controlled stably and with the highest precision.

Since mid-2022, MESACON Messelektronik GmbH Dresden has been part of the Metal business unit of EMG Automation GmbH. Our measuring systems are now offered there as the EMG iTiM product family for thickness and coating thickness measurement. They complement the product portfolio of EMG Automation's quality assurance systems, especially in steel and aluminium service centres for monitoring product quality. You can find more information on this at EMG iTiM.

Solutions for cold rolling

- Thickness gauges for centre and profile measurement in cold rolling mills

- Speed measurement for mass flow control - In the cold rolling mill on tandem and reversing stands as manipulated variable for the controls

- In pickling, inspection and partial plants for checking the specified values

Solutions for Steel and Aluminium Service Centres

- Control of the incoming material thickness

- Precise strip thickness measurement also for shears and slitting lines

- Provision of thickness data for end customers or downstream processes

- Increased material yield

- Combined visualisation e.g. for thickness and width

- Coil and plate-related provision of thickness data

Solutions for Automotive

- Control of the incoming material thickness

- Precise strip thickness measurement also for shears and laser cutting machines

- Blank-related provision of thickness data

- Reduction of rejects in the further production process

- Combination of further EMG quality assurance systems, such as roughness measurement, width measurement, etc. possible

Have we caught your interest? Get in touch!

The right system for your requirements!

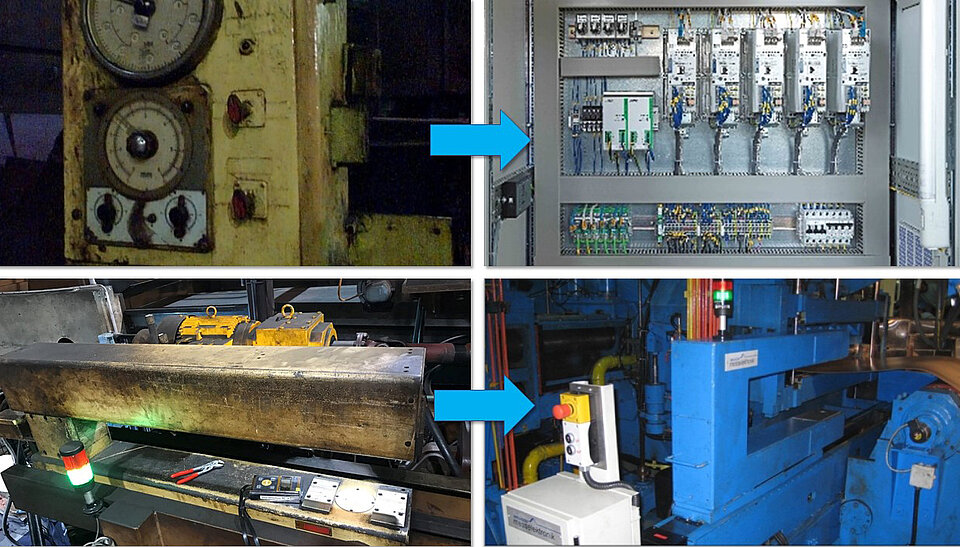

EMG can now help you optimally implement your technological goals and production requirements with the EMG iTiM thickness measurement technology. Existing plants can also be effectively modernised by seamlessly integrating our thickness measurement systems into your production line.

The focus is always on reducing your effort and material costs!

For example, existing isotope sources can often be reused and the special plug-and-play devices can be installed within just a few hours. The EMG software solutions, which can also be integrated into existing systems, also contribute to maximum effectiveness. In addition, all our thickness measurement solutions undergo an endurance test in our in-house endurance test facility.

Detlef Jährling, Product Manager EMG iTiM

Please contact me:

T: +49 351 8717160

E-Mail: detlef.jaehrling@emg-automation.com